The PROCESS SUITE of software products was developed by experienced industrial engineering specialists with a view to high practical suitability. The methodical and functional know-how acquired in many years of consulting experience was implemented 1:1 in software applications that make work easier. Not least from the daily work with conventional aids the idea arose to develop tools that consistently implement today’s state of the art ratio approaches. The individual modules of the PROCESS SUITE are briefly described below. A detailed description of the products can be found on the website www.process-suite.com

PROCESS TM is an internet-based, easy-to-use solution for the modern execution of time recordings and evaluations. The user downloads a digital clock from the product website to his Pocket PC, Smartphone or now from version 4 directly to his Windows Tablet. Time recording can be started immediately after instalment.

The evaluation of the time data is just as simple: The user uploads the data to the PROCESS-TM server. A 1:1 representation of the classic time recording sheet with all data is generated immediately. The application has a wide range of evaluation options and graphic display options. In addition to the execution and evaluation of time recordings, the system offers database-driven management of time modules (process elements).

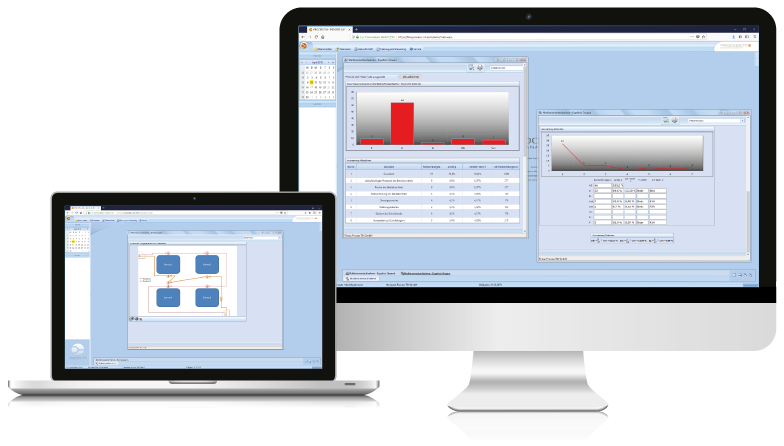

This makes it possible to design and evaluate new processes using the integrated Process Designer. The structure of a new process can therefore first be simulated and evaluated.

In the latest version, the PROCESS MM module has now been fully integrated into the time management environment. Thus, in addition to classical time recording, it is possible to carry work-sampling and distribution time studies. The ability to create and manage routings rounds off the software’s range of functions. Thus, the application is a complete solution for your time management.

PROCESS TM is offered in 2 variations: Server version: Integration into the existing IT infrastructure of the company or as a

SaaS version: Online solution that can be operated via any browser. (Software as a Service)

With the PROCESS MM module, simple but also very complex activity-sampling studies can be carried out with little effort to determine distribution time surcharges or time share analyses. Today PROCESS MM is an essential part of the time management software PROCESS TM.

PROCESS PM is a practice-tested intranet solution for premium wage calculation, which covers the range of functions up to the transfer to gross wage accounting in personnel administration.

Maximum complexity can be mapped, as the software was originally developed for the particularly demanding logistics sector. The requirements in the logistics sector are characterised by a particularly high number and variety of orders.

The solution supports the administration of all premium types and wage types within the premium wage system, the administration of parameter data (time modules) and master data. Daily or monthly performance overviews of the individual premium areas can be generated at the push of a button.

Individual premiums, group premiums and average premiums can be calculated. The integration of quality bonuses is also prepared as standard. The target time module calculates the exact target times using order data from a wide variety of interfaces. Manual input via time tickets is therefore unnecessary. Today, for example, premium management can be carried out with a minimum of personnel.

An additional benefit is the generation of a data warehouse that provides management with constant access to current key figures, order and customer structures over time.

Today, the PM system is often used without the remuneration component to monitor and, if necessary, control the productivity development of a wide range of company structures.

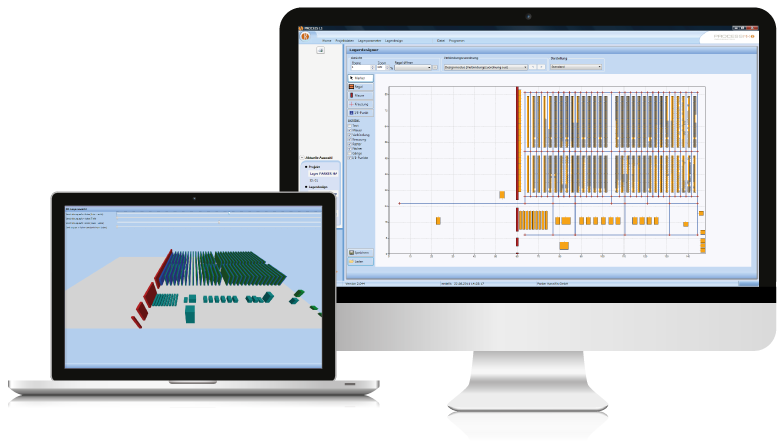

PROCESS MX is a software for mapping bearings. With the help of a graphical editor, shelves, wall elements, order starting points and path graphs are mapped to scale on a virtual storage area.

The software manages the master data required to set up a warehouse in clearly structured dialogs. PROCESS MX can manage any number of projects in a structured way using an Explorer. The shelf editor contained in PROCESS MX allows detailed processing of a shelf down to each individual storage compartment to which several descriptive parameter values can be assigned.

Convenient Microsoft Excel import, and export interfaces are available for simple storage compartment and parameter renaming.

The distance values between any storage compartments and transfer points can be determined very precisely by means of an easy-to-create route graph; the unidirectional passability of individual routes can be specified.

A suitable . net library (dll) can be provided to integrate the distance calculation into your own program code.

PROCESS MX is often used in conjunction with premium wage systems in logistics to precisely calculate the variable order paths of order pickers and replenishment drivers.

The bearing created with MX can also be viewed in a 3D view. That way, the entered parameters can be quickly checked for plausibility.

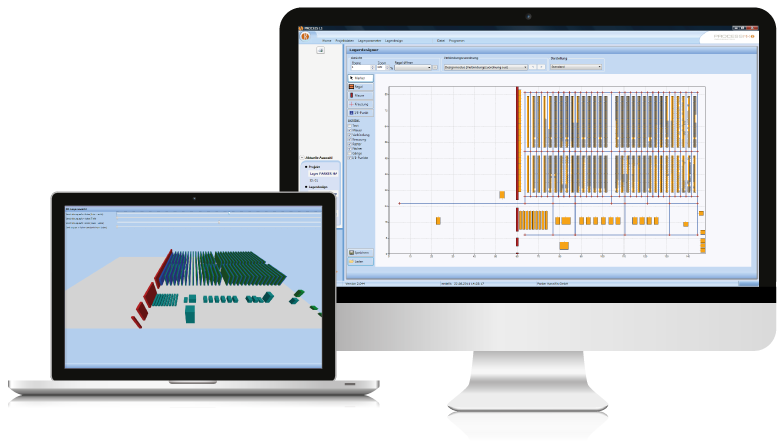

PROCESS LS is the unique solution for the optimization of complex warehouse layouts using real data-based simulation calculations. The “ideal” warehouse is designed by simulating the effects of changes in the warehouse layout on personnel demands and productivity based on real order data.

The simulation is carried out on the basis of standard times and hourly costs. The integrated ABC analysis identifies the “fast-moving items” and determines their storage locations accordingly. The choice of the primary evaluation period is completely flexible.

The variations of the warehouse layout to be decided on can finally be evaluated according to the criteria ‘time’, ‘costs’ and ‘aisle load’.

PROCESS LS contains the module MX. First, the existing bearing or the new bearing to be planned is created graphically and geometrically. This includes, for example, storage aids, picking and reserve zones and packing restrictions. In the initial situation, the current warehouse occupancy can be mapped. In the different simulation variations, however, automatic warehouse allocation can also take place.

The program is already being used successfully by well-known major distribution logistics companies.

For more details on our software products, please visit our website PROCESS SUITE.